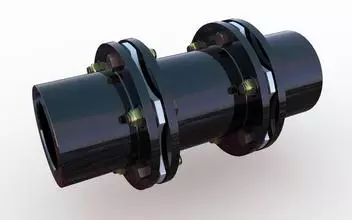

Features and Application of Diaphragm Coupling

Laminated membrane coupling makes the best of high anti-fatigue characteristics of metal diaphragm material to give integral coupling advantages of light quality, reliable work, no lubrication, convenient maintenance, etc. It is made of several groups of diaphragm (stainless steel thin plates) using bolt crisscross and two halves of coupling, each group diaphragm composed of several pieces fold sets, and diaphragm can be classified into connecting rod type and different shapes of full chip.

Diaphragm coupling depends on elastic deformation of the diaphragm to compensate for the relative displacement of the two leagued axes, which is a high-performance elastic metal flexible coupling components without the need of lubrication, besides, it is of compact structure, high intensity, long service life, no rotating clearance and not influenced by temperature or oil pollution, has the characteristics of acid and alkali resistance as well as corrosion resistance. As a result, it is suitable for shaft transmission under working condition of high temperature, high speed and corrosive medium, and is widely used in all kinds of shaft transmission of mechanical device, such as water pump (especially high power), chemical pump, fan, compressor, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters) and high-speed power transmission system of ships. After balancing, application in high-speed transmission shafting is common.

Compared with gear coupling, diaphragm coupling has no relative sliding, no need of lubrication and sealing, no noise, basically no need of repairing and is convenient to produce, can replace gear coupling partly. Diaphragm coupling has been very popular in developed countries around the world, in practice the intermediate shaft type is commonly used to improve compensation offset performance of the two axes.